Let's find out how to keep your machine clean.

Some sections of the machine need more attention when it comes to cleaning. Make sure to have your machine in tip-top shape to lenghten your parts life cycle.

Daily cleaning

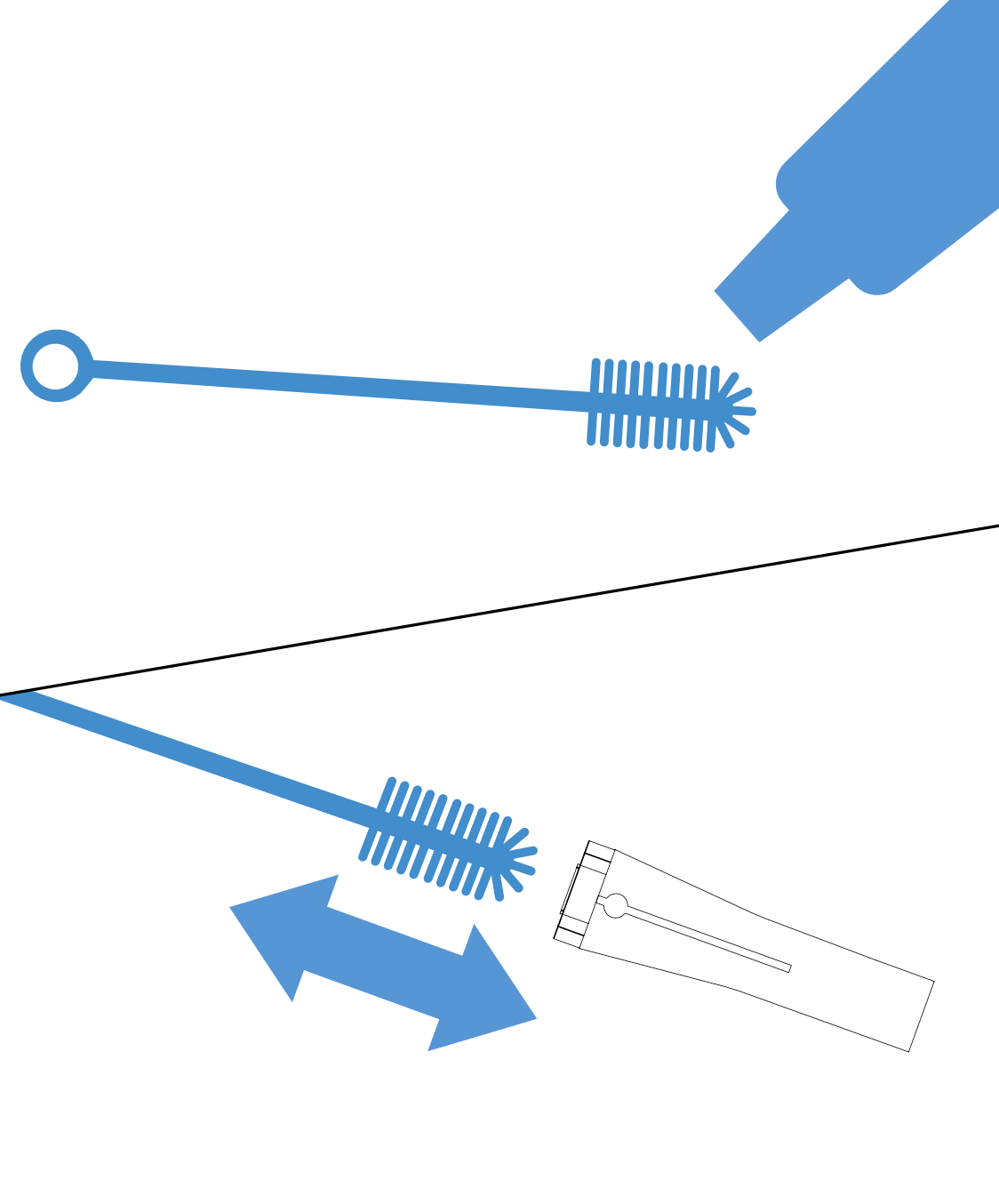

There are bellows in your milling machine to protect rails and guides. These rails and guides are essential for precise axis movements. Make sure to clean the Y axis bellows the upper section and lower side sections daily, so the dust and particles won't clog and prevent the axis movement.

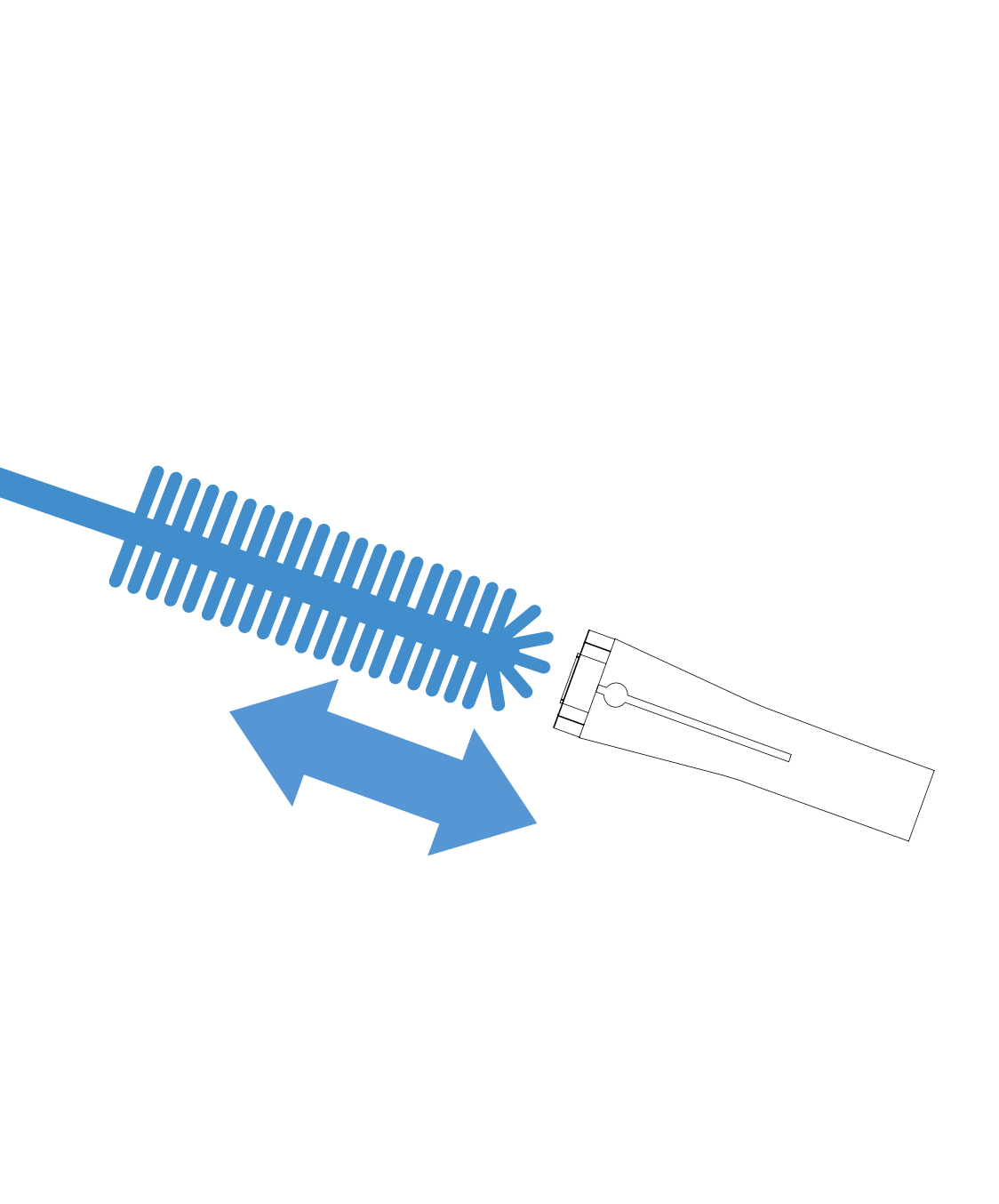

You need to clean the bellow link threads with help of a brush.

Cleaning back bellows of Y axis can be hard since B axis metal sheet blocking your way. Push the particles to the sides with help of a brush.

Lastly you need to clean the side edges of your bellows.

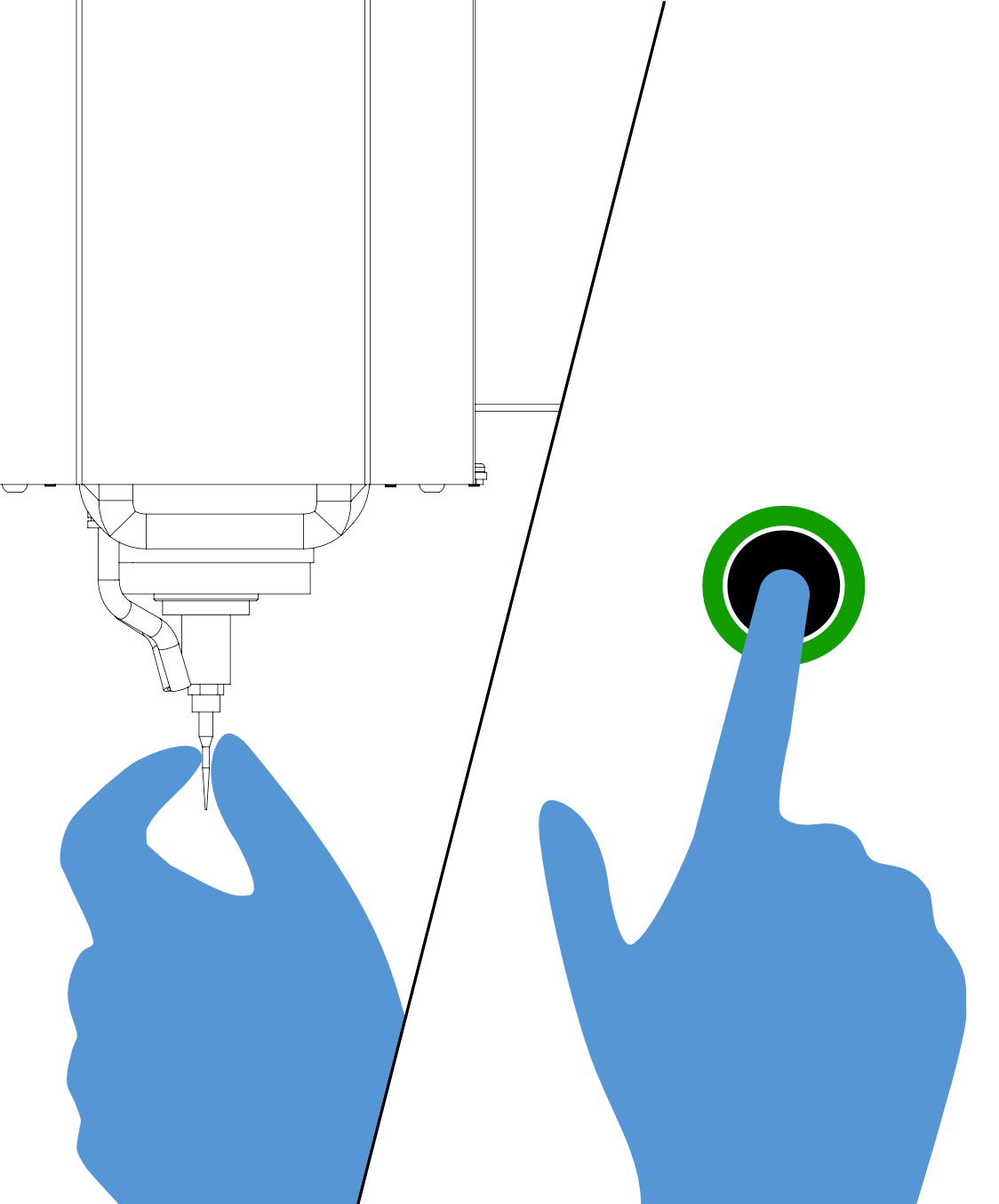

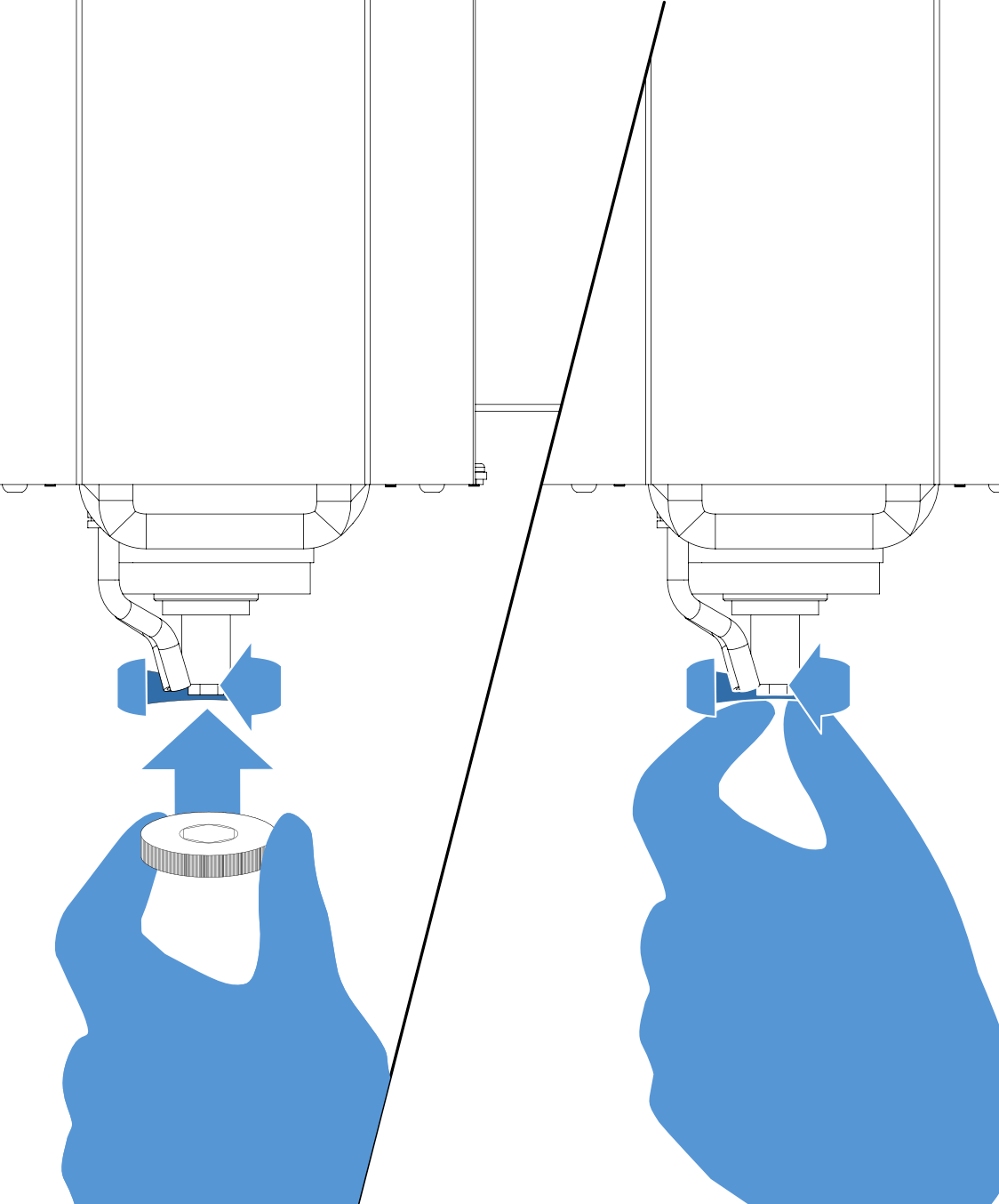

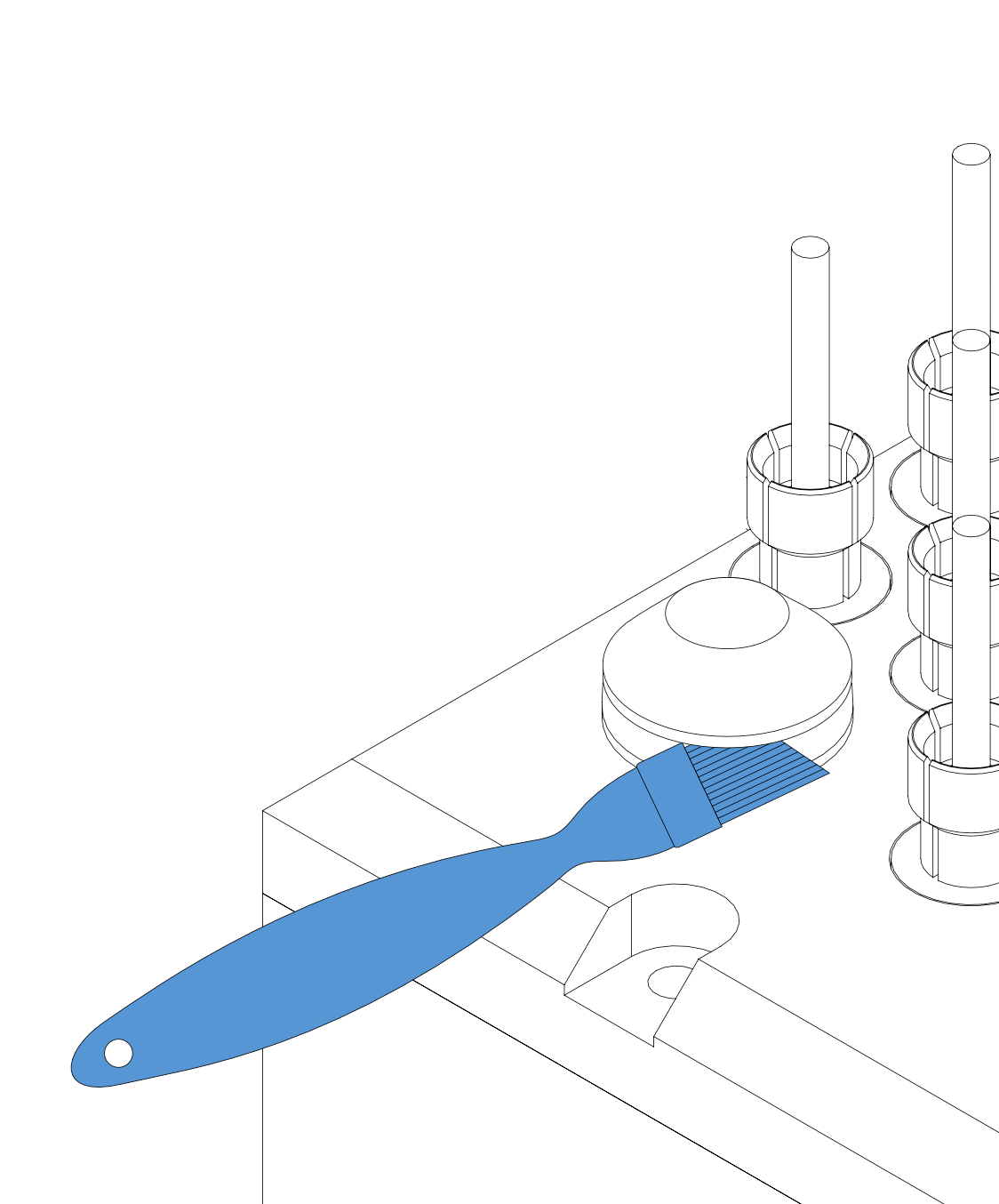

Collet cleaning

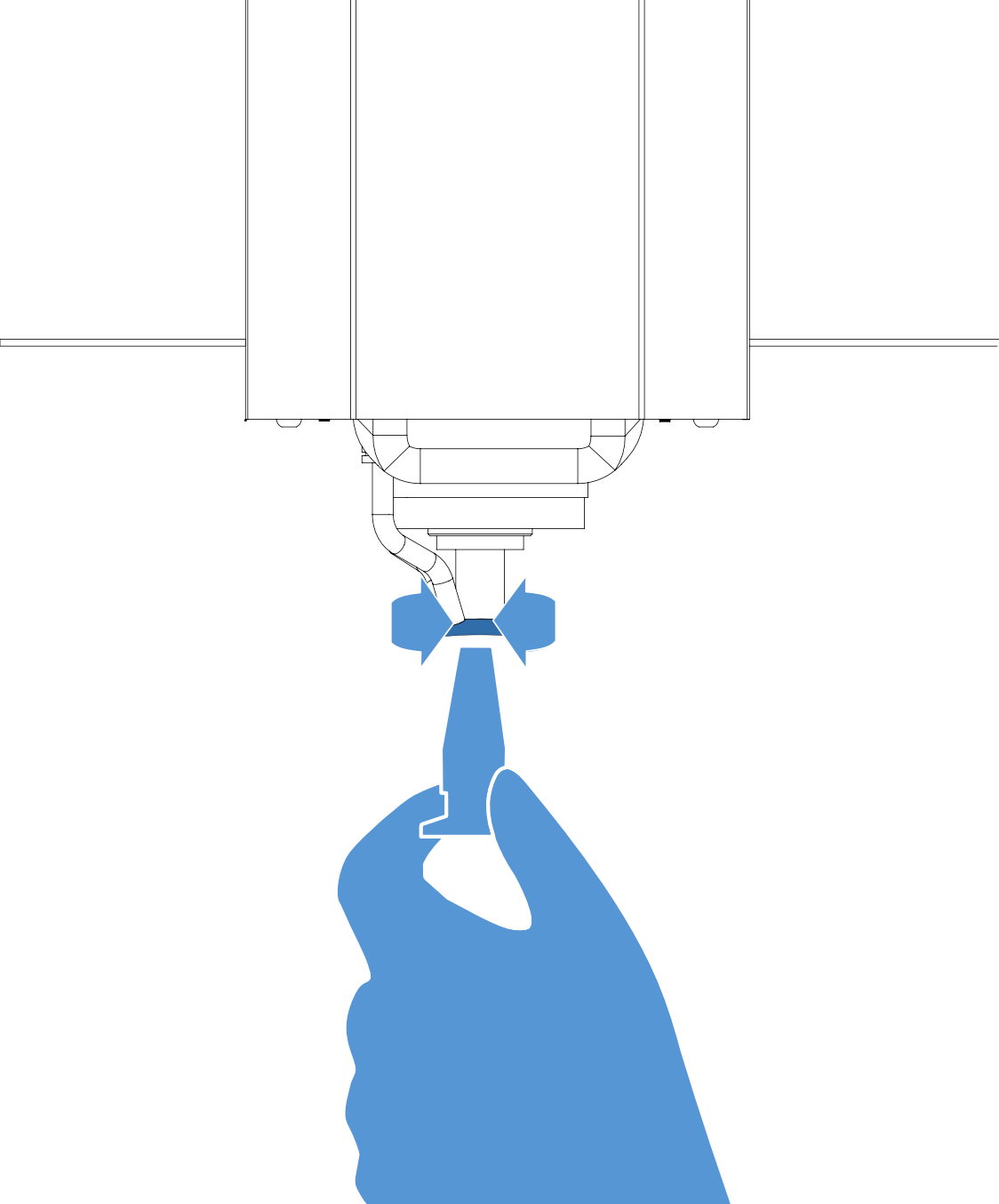

The spindle is both the most powerful and the most sensitive. part of your machine. Even a slight vibration can cause imperfections. Make sure to clean the spindle collet once a month with the collet cleaning kit you receive with the machine.

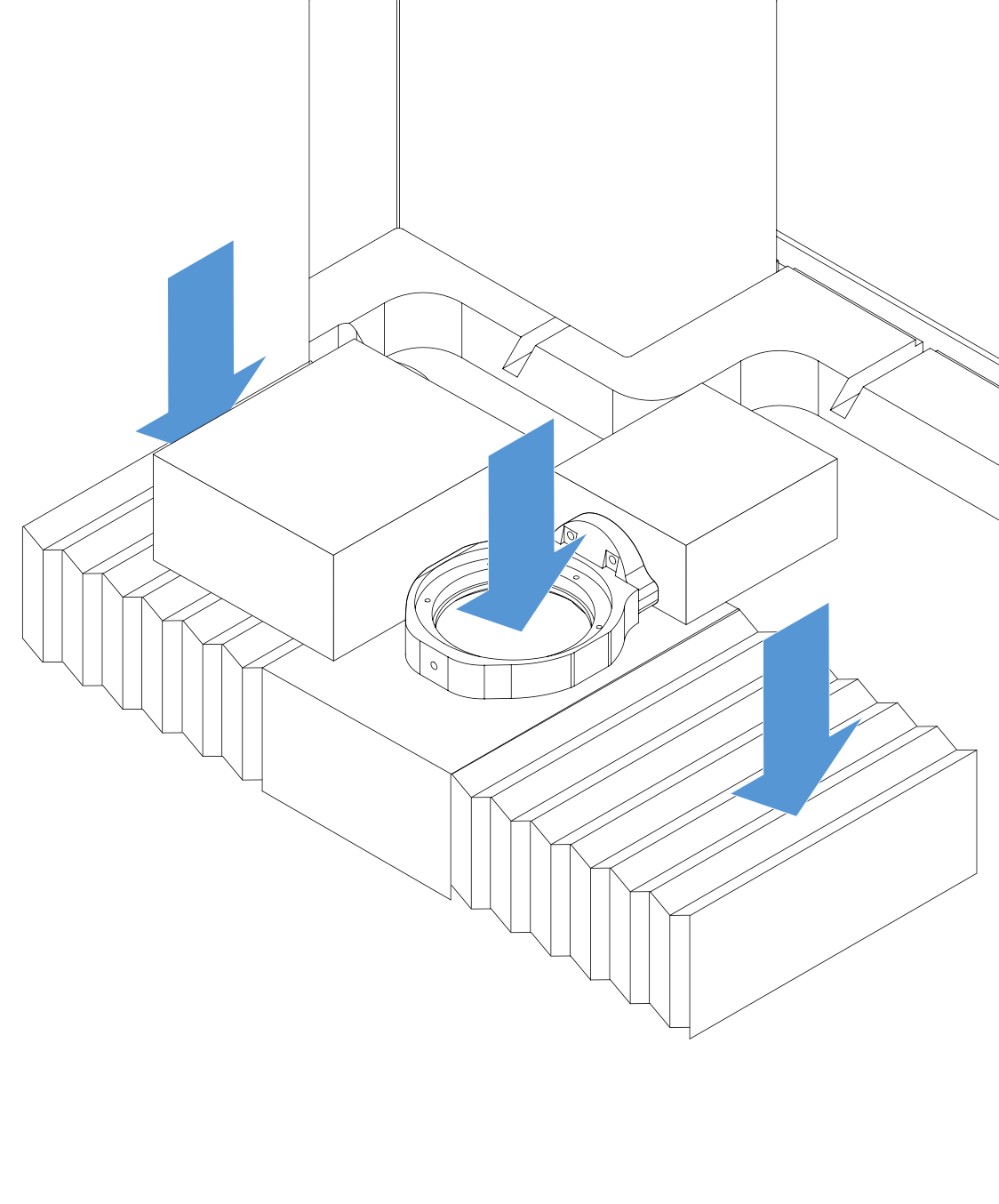

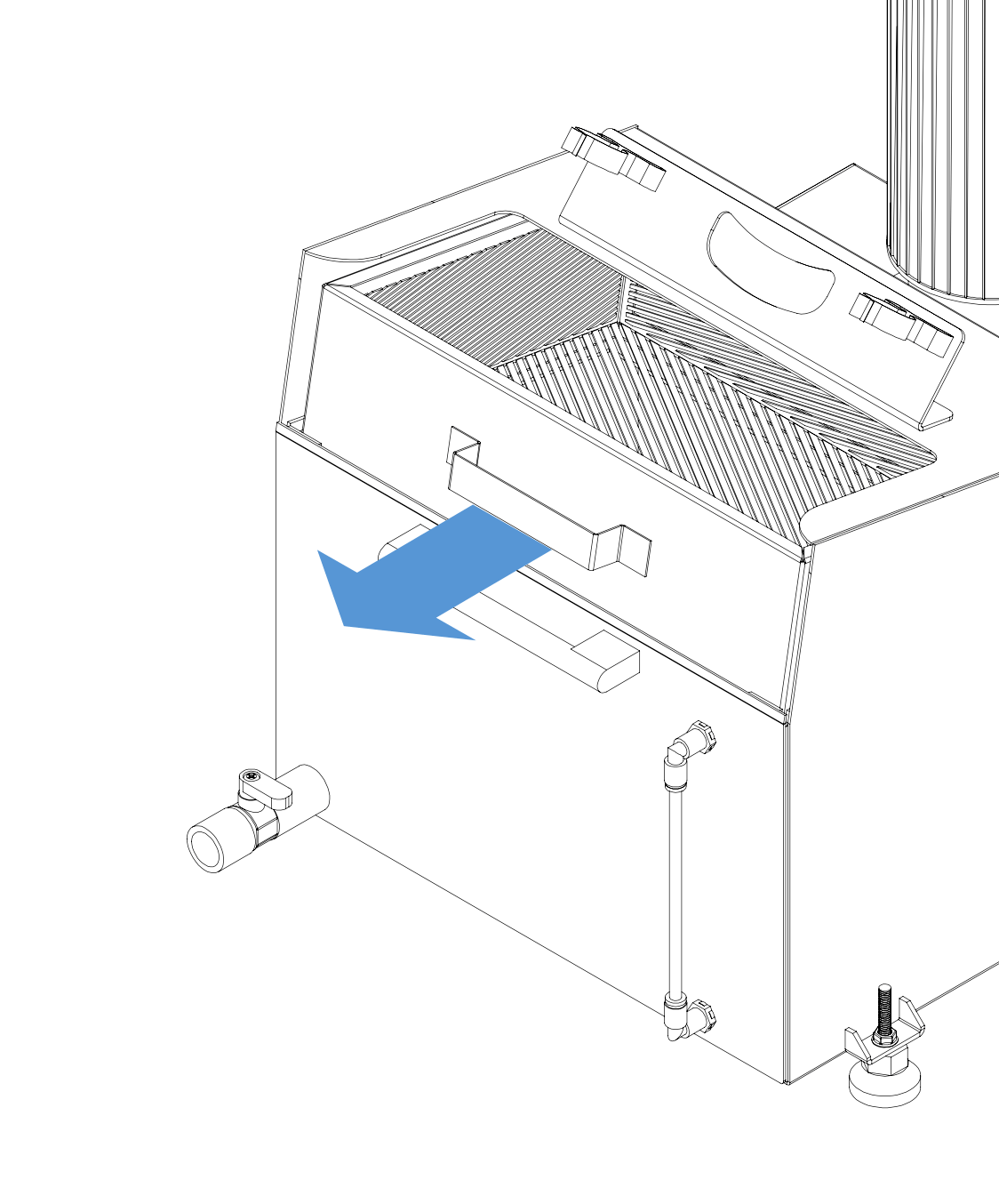

Drains cleaning

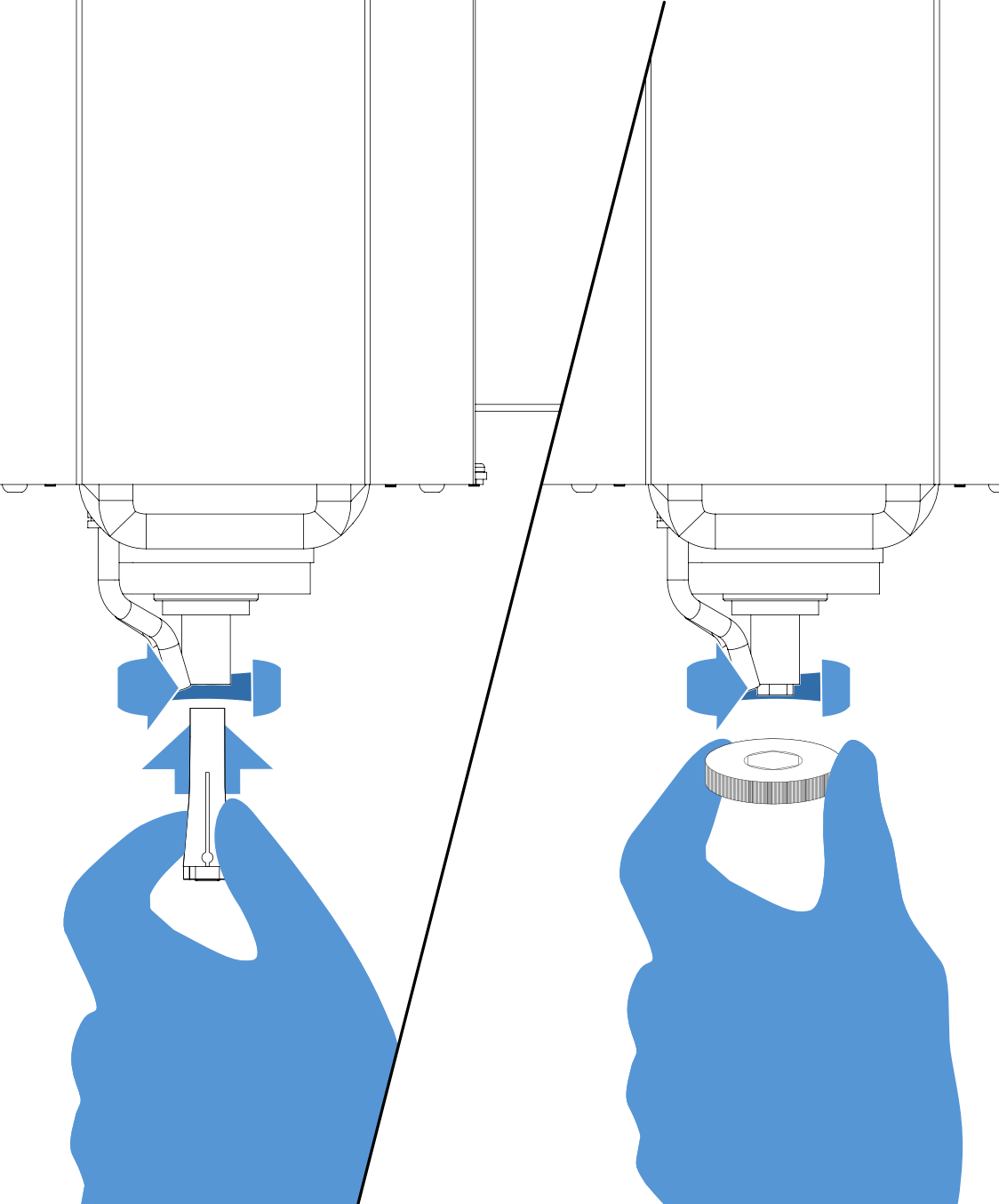

For better cutting liquid circulation, drains inside the machines should be checked and cleaned once a month.

Zirconia dust, or metal shavings can collect inside the 90 °C fitting and may prevent drainage.

Fitting can be cleaned by clearing blockage with a stick-like object.

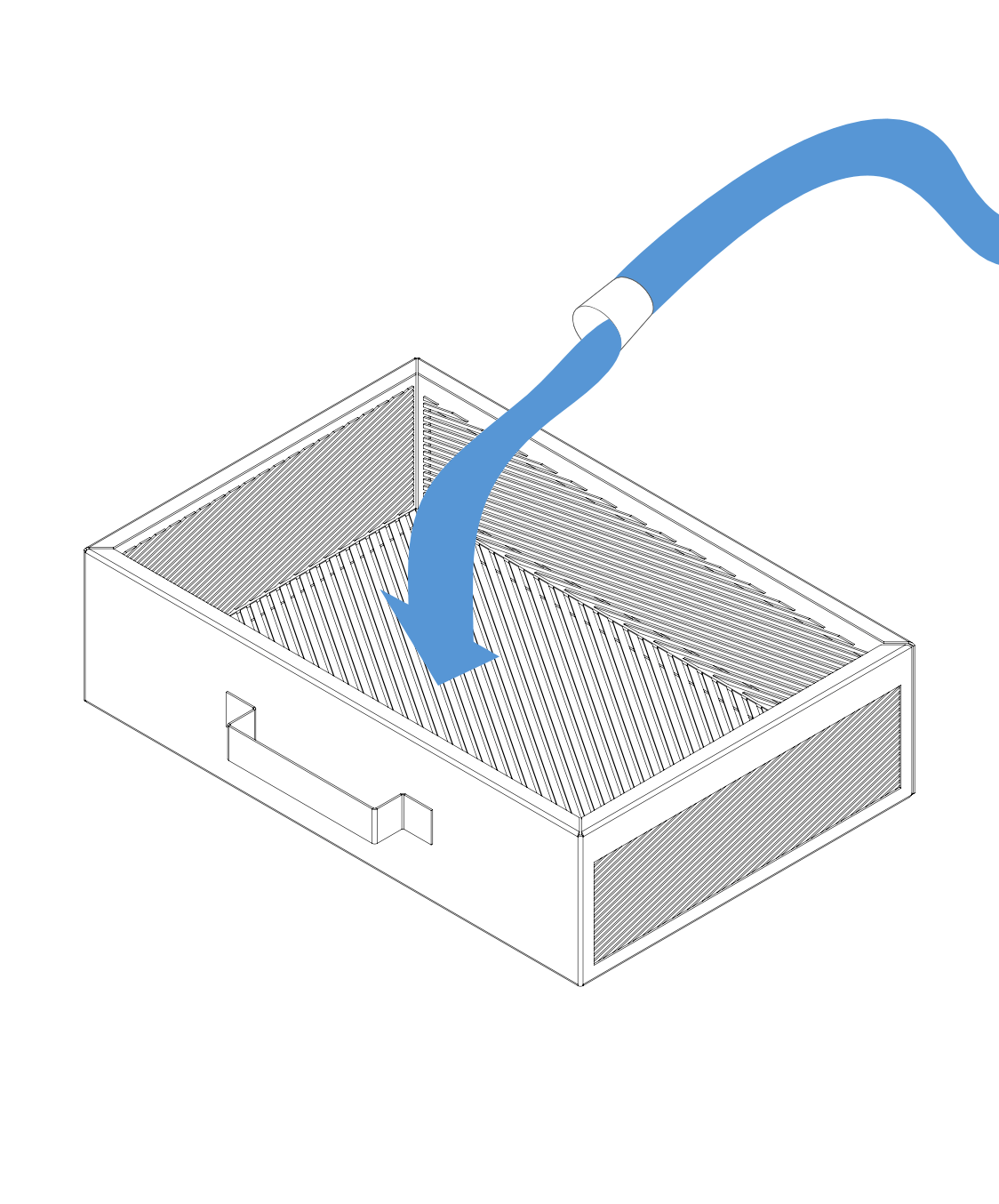

Liquid tank filter cleaning

Dust and particles are filtered from the cutting liquid before the liquid reenters circulation. In order to have a clean and filtered liquid that can improve tool lifespan significantly, the filter must be cleaned regularly.

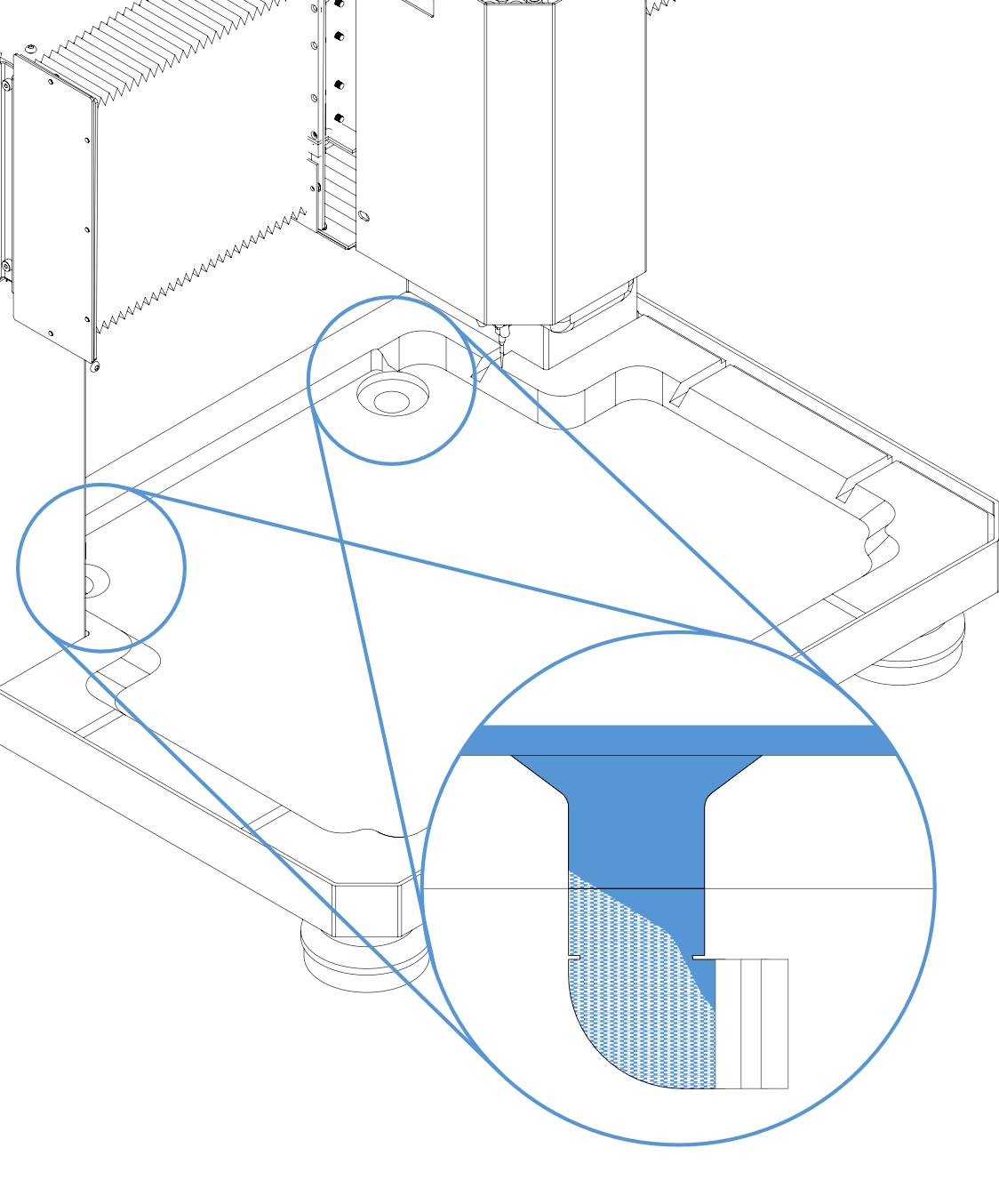

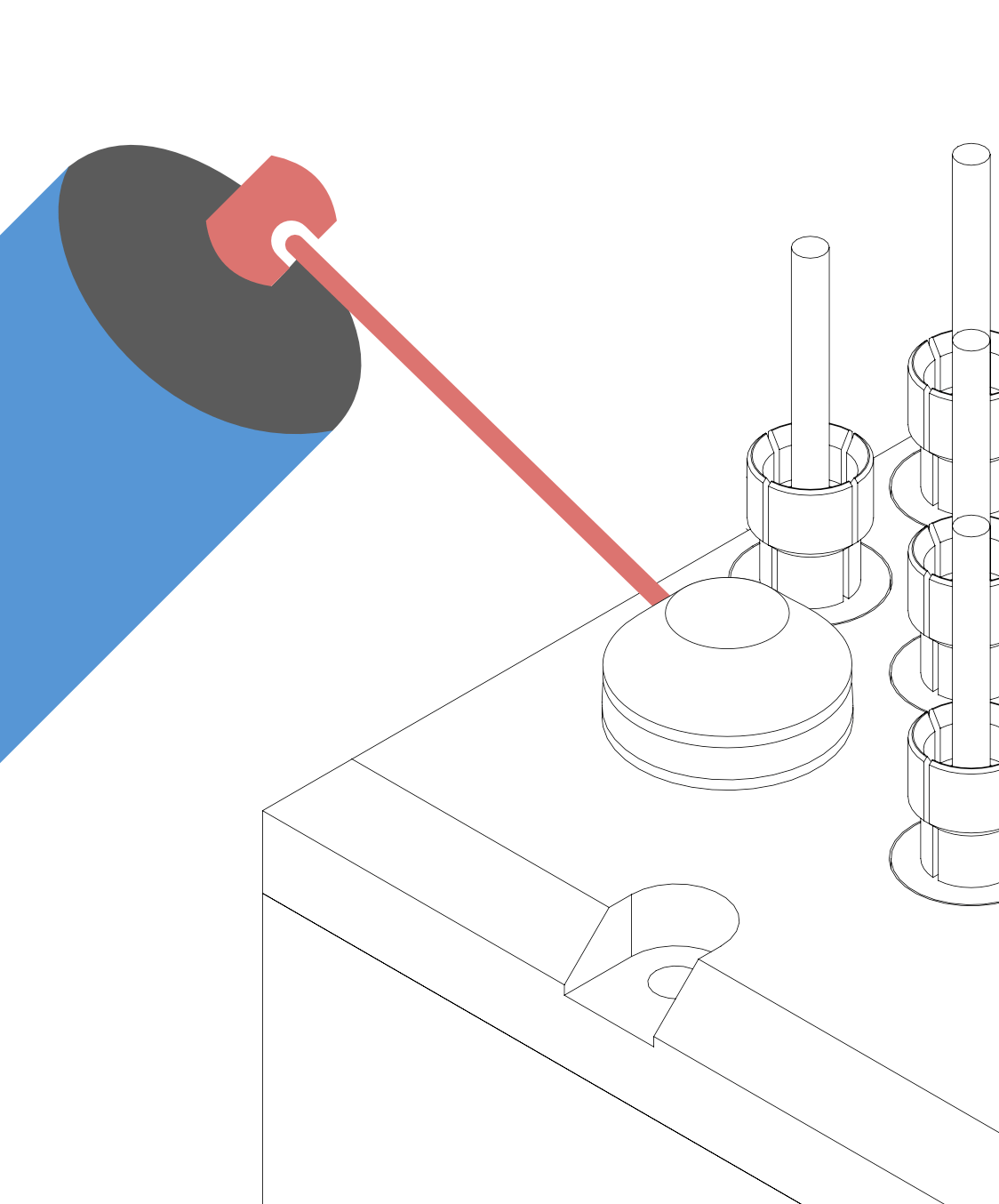

Tool measurement sensor probe cleaning

The dust and particles beneath the measurement probe can pile up and prevent the movement of the probe. This may produce miscalculations, can cause tool breaking, or even worse machine malfunction.

The probe must be checked weekly.

Deep cleaning

Deep cleaning requires you to remove the machine cover to clean hard-to-reach areas of your machine easily.

After you have removed the front cover clean your machine throughly with an electric vacuum cleaner. Zirconia dust may cause malfunction for regular vacuums, we suggest an industrial vacuum.